Evaluation of Different Rates of Insecticide Plinazolin® Sc200 for Control of Fruitworms and other Fruit-feeding Insect Pests in Staked Tomato Production

Galen P. Dively and Terry Patton - Department of Entomology, University of Maryland

In cooperation with: Erin Hitchner -Research and Development Field Scientist, Syngenta Crop Protection

PLINAZOLIN® technology is the trademark of a new active ingredient that provides a novel mode of action that helps growers manage a range of resistant and difficult to control insect pests, through targeted spray programs. The University of Maryland has been working with Syngenta to determine the minimum dosage of the insecticide required to effectively control fruitworms, as well as to generate the necessary data required by EPA for product registration. Over the last four years, trials have been conducted at the Central Maryland Research and Education Center, Beltsville, MD.

In 2022, a field experiment evaluated three application rates of plinazolin SC200 for control of fruit-feeding lepidopteran pests of tomato. Other insect pests evaluated included stinkbugs and thrips. Different rates of plinazolin were compared to the following commercial standard insecticides at their labelled rates: Radiant, Coragen, Besiege, and Intrepid. Bedding trays of tomato seedlings (‘Fresh Mountain Plus’) were grown in the University greenhouse and transplanted on black plastic mulch on June 16. The field site consisted of Hammonton loamy sand soil and was previously planted for many years in various vegetable crops, most of which served as host plants for lepidopteran pests. The experiment represented a typical late-season production of tomato and was timed for fruiting to coincide with peak fruitworm activity. Plots were laid out in a randomized complete block design with four rows, each treated as a replicate block and divided into nine plots. Seven insecticide treatments and two untreated controls were randomized within each row. Each plot consisted of one row 20 ft long and spaced 6 feet apart. Ten plants were spaced 24” apart in each plot. Tomato growth was managed according to commercial trellis practices, including staking between every two plants, pruning suckers and axil shoots to encourage apical growth, and stringing three times to support vertical plant growth. Irrigation were applied as needed through drip lines under the plastic mulch to maintain recommended soil moisture. Fertility requirements consisted of 60 lbs/acre of nitrogen incorporated into the soil prior to applying the plastic mulch and then followed up with additional nutrient feeding through the drip lines. Fungicides were applied weekly five times starting August 2 using an air blast sprayer to control foliar diseases. Different classes of fungicide products were tank mixed and rotated during the last four applications to control leaf blight infection and reduce the risk of disease resistance.

Overall population pressure of lepidopteran pests was monitored with pheromone lures of tomato fruitworm (Helicoverpa zea) and yellow striped armyworm (Spodoptera ornithogalli), in Texas wire cone traps and green bucket traps, respectively. Traps were placed next to the experiment site, and moth captures were recorded daily during weekdays during the treatment and harvest periods. Prior to initiation of treatments, plots were visually inspected weekly for evidence of any defoliation and feeding on green fruit. On August 8, the first application of each treatment was applied when the crown green fruit reached 75% of its mature size. The rationale for this early timing was to initiate control of lepidopteran larvae on the foliage before they started feeding on the fruit. Four subsequent applications were applied weekly on August 15, August 22, August 29 and September 5. Each treatment was applied using a CO2 backpack sprayer using a drop nozzle boom with five hollow cone nozzles covering each row, two directed on each side of the foliage and one over the top. The applicator walking time to cover each plot was calibrated to deliver 33 gallons/acre at 40 psi, and the amount of each chemical was added proportionately to one gallon in the spray tank. All treatments were applied with a modified vegetable oil surfactant blend DYNE-AMIC at the rate of 0.25% of the spray volume.

Plants were examined for symptoms of phytotoxicity after each application. Direct assessment of fruit damaging insects was not performe d because the canopy structure of the trellis plants made it impractical to visually inspect and count the number of larvae. Sampling for damaged fruit commenced on September 2 when one-third of the tomatoes reached marketable maturity, characterized by attaining pink-red color and maximum size. Repeated harvests of similar fruit maturity were made on September 9 and 16. At each harvest, samples of tomatoes were removed and examined for damage caused by fruitworms, stink bugs, and thrips. Data were also recorded on the number of fruit with rot symptoms unrelated to insect feeding. Data from the two untreated controls were averaged for each replicate by sampling date prior to analysis. Because of differences in the number of tomatoes harvested per plot, damaged fruit counts were converted to percentages of each pest injury category and transformed using the arsin function to normalize data if necessary. For each pest group, the mixed model ANOVA procedure tested for treatment, harvest date and treatment by harvest date effects with replicate block treated as a random factor. The pdiff option was used to test for significance among multiple mean comparisons at the 5% probably level.

d because the canopy structure of the trellis plants made it impractical to visually inspect and count the number of larvae. Sampling for damaged fruit commenced on September 2 when one-third of the tomatoes reached marketable maturity, characterized by attaining pink-red color and maximum size. Repeated harvests of similar fruit maturity were made on September 9 and 16. At each harvest, samples of tomatoes were removed and examined for damage caused by fruitworms, stink bugs, and thrips. Data were also recorded on the number of fruit with rot symptoms unrelated to insect feeding. Data from the two untreated controls were averaged for each replicate by sampling date prior to analysis. Because of differences in the number of tomatoes harvested per plot, damaged fruit counts were converted to percentages of each pest injury category and transformed using the arsin function to normalize data if necessary. For each pest group, the mixed model ANOVA procedure tested for treatment, harvest date and treatment by harvest date effects with replicate block treated as a random factor. The pdiff option was used to test for significance among multiple mean comparisons at the 5% probably level.

Fruit maturation and yield were considered normal for trellis tomato production. However, high temperatures caused sun scalding on exposed fruit in the top canopy, leading to some splitting and discoloration around the stem region of the fruit, particularly during the last harvest date. All pink-red tomatoes were removed and examined during the first harvest date, averaging 37.3 fruit per plot (ranging from 16 to 68). A random sample of 50 marketable fruit were harvested in most plots during the last two harvest dates. No signs of phytotoxicity effects on the

overall plant health and vigor were evident in any plots that could be related to the treatments. On the last assessment date, there was moderate levels of necrosis-type injury on the top canopy due to late blight infection and environmental stress; however, this injury was equally present in all treated and untreated plots.

Fruitworm injury was caused almost entirely by the yellow striped armyworm, with no evidence of tomato fruitworm presence. This was surprising since pheromone captures of H. zea moths were very high during the fruiting period, and nearly 100% of the ears in adjacent untreated sweet corn plots were damaged by corn earworm. Averaged over sampling dates, fruitworm injury was recorded on 13.5 % ± 1.71 SE of the harvested fruit in the untreated plots. Injury by stinkbugs (mainly Euschistus servus, Halyomorpha halys) and thrips was also recorded on an overall average of 9.8 % ± 1.67 SE and 1.6 % ± 0.57 SE of the tomatoes in the untreated plots, respectively. Thrips injury was highly variable among plots and lower than the normal infestation levels previously experienced at this site. Altogether, the combined feeding injury of all fruit-feeding insects affected 24.9 % ± 2.78 SE of the marketable fruit, although many tomatoes exhibited more than one type of injury. Fruit showing symptoms of rot (unrelated to insect feeding) ranged from 1.62% to 6.38%. However, there were no treatment or treatment by date effects on the number or percentage of rotted fruit (F(7,81) = 1.50, P = 0.180).

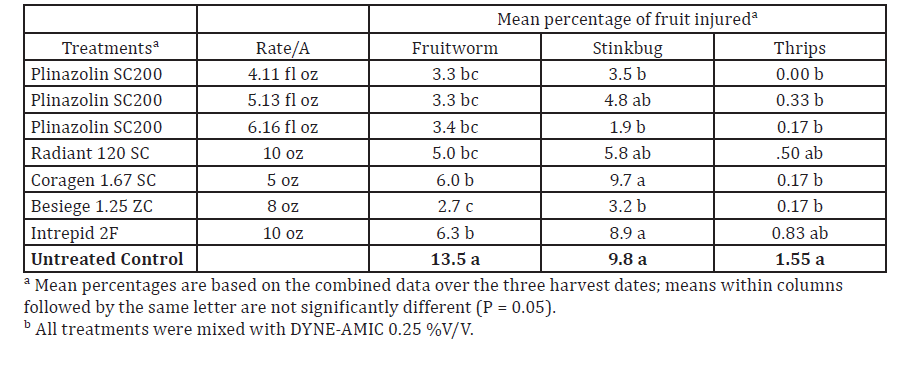

The treatment by date interaction effect was not statistically significant for any of the pest injury variables. The main effect for sampling date was also not significant, except for the percentage of stinkbug injury which decreased over the three sampling dates. Table 1 summarizes the treatment effects for each of the three fruit feeding insects, based on data pooled over all sampling dates. For fruitworms, all insecticide treatments significantly reduced the percentage of fruit injury by 53.5% to 80.1% compared to the untreated control (F(7,95) = 10.12, P<0.001). The plinazolin treatments showed no significant trend of increasing control with higher rates and also overall control of ca. 75% was not significantly different from any of the standard insecticides. Besiege provided the highest level of control (80.1%) but was only significantly different from levels of control by Coragen (56.0 %) and Intrepid (53.5%).

For stinkbugs, only plinazolin treatments and Besiege significantly reduced the percentage of fruit injury compared to the untreated control (F(7,95) = 4.5, P<0.001). Rates of plinazolin significantly reduced stinkbug injury by 50.7 to 80.2 % but there were no significant differences among rates and only weak numerical evidence of better control at the high rate. All plinazolin rates also performed significantly better that the standard insecticides, except for Radiant (40.9% control) and Besiege (67.0 % control) which provided levels of stinkbug control comparable to the plinazolin treatments. As expected, Coragen (1.5% control) and Intrepid (9.6% control) were clearly the least effective against stinkbugs. For thrips, despite the highly variable data due to the low infestations, all treatments except for Radiant and Intrepid significantly reduced the percentage of fruit injury compared to the untreated control (F(7,95) = 2.47, P = 0.023), and there was no evidence of a plinazolin rate response.

In summary, the key objective was to determine if increasing the rate of plinazolin will result in increased control of lepidopteran pests in tomato. Altogether, although overall infestations were considered light to moderate, results showed no evidence of a rate response against fruitworms, stinkbugs and thrips.

Table 1. Effects of different rates of plinazolin SC200 compared with standard commercial insecticides for suppression of fruitworms, stinkbugs and thrips causing tomato fruit injury. Beltsville Research and Education Center. 2022.

Back to Roots in Research Beltsville